⚙️ 3D PRINTING

Advanced Additive Manufacturing for Industrial and Defense Applications

Smith & Company integrates cutting-edge 3D printing technologies into our precision manufacturing platform to deliver high-performance components with speed and flexibility. From rapid prototypes to functional end-use parts, our additive manufacturing capabilities support defense, aerospace, medical, energy, and industrial markets.

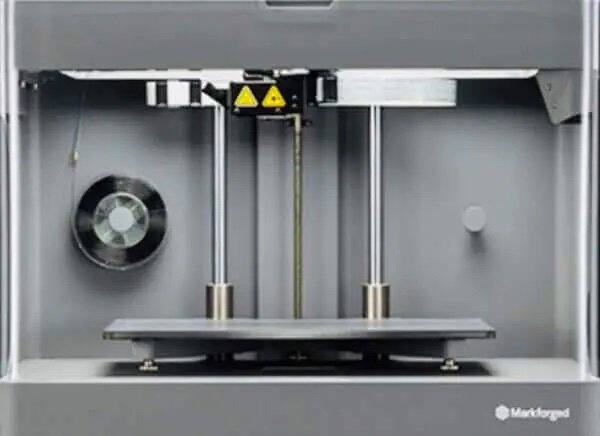

🧱 Composite 3D Printing

Our industrial composite printing system enables the production of strong, lightweight parts ideal for fixtures, tooling, and functional applications. Reinforced with continuous fibers like carbon fiber and Kevlar, these components offer high strength-to-weight ratios and exceptional durability.

- Materials: Carbon Fiber, Kevlar, Onyx, Nylon

- Applications: Jigs, fixtures, tooling, and prototypes

- Benefits: Lightweight, strong, and production-ready

🏗️ Metal 3D Printing

Our metal additive manufacturing system is designed to produce complex geometries and functional metal parts with fast turnaround. Ideal for low-volume production, tooling inserts, and high-strength prototypes, it reduces lead times while expanding design possibilities.

- Materials: Stainless Steel, Tool Steels, Inconel, Copper

- Applications: End-use parts, custom tooling, rapid prototypes

- Benefits: Durable, cost-effective, design-flexible

🖥️ Integrated Digital Workflow

Our 3D printing workflows are embedded into our digital manufacturing ecosystem—enabling seamless quoting, tracking, and part validation. From CAD to final inspection, we maintain traceability, compliance, and repeatability at every step.

- Rapid Prototyping: Accelerate product development and iteration

- On-Demand Production: Reduce inventory and adapt quickly to change

- Customization: Tailor parts to unique program or field-specific needs

📞 Let’s Collaborate

Discover how our additive manufacturing solutions can support your next project—from functional prototypes to production-ready parts.

Contact Our Team